Direct-to-film printing is a revolutionary technology that has gained popularity in recent years. This innovative method allows designers and creators to print their designs directly onto a film and transfer them seamlessly onto various surfaces, such as fabric. In this article, we will delve into the benefits of direct-to-film printing and how it has transformed the design industry.

What is Direct-to-Film Printing?

Direct-to-film printing, also known as film printing or film sublimation, is a process that involves printing a design onto a specialized film using a digital printer. The design is then transferred directly from the film onto the intended surface, such as fabric, through a combination of heat and pressure.

This method eliminates the need for traditional transfer methods like screen printing or heat transfer vinyl, which often require multiple steps and can be time-consuming. With direct-to-film printing, the design is printed onto the film in a single step, resulting in a faster and more efficient process.

The Benefits of Direct-to-Film Printing

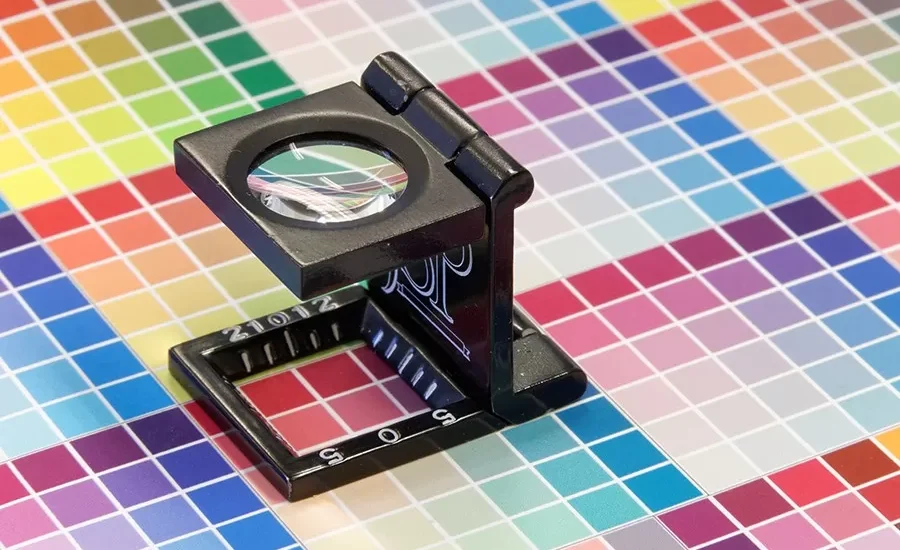

1. High-Quality Prints: Direct-to-film printing offers exceptional print quality with vibrant colors and fine details. The advanced digital printing technology ensures that every nuance of the design is accurately reproduced on the film, resulting in stunning and professional-looking prints.

2. Versatility: Direct-to-film printing is highly versatile and can be used on a wide range of surfaces, including fabrics, ceramics, glass, and more. This flexibility opens up endless possibilities for designers and allows them to explore various mediums for their creations.

3. Durability: The prints created through direct-to-film printing are highly durable and long-lasting. The design becomes a part of the surface it is transferred to, ensuring that it does not fade, crack, or peel over time. This makes it an ideal choice for items that undergo regular use or require frequent washing, such as clothing or accessories.

4. Cost-Effective: Compared to traditional printing methods, direct-to-film printing can be more cost-effective, especially for small to medium-sized production runs. The elimination of multiple steps and the ability to print on-demand reduces production costs and minimizes waste.

5. Time-Efficient: Direct-to-film printing significantly reduces production time as it eliminates the need for additional steps like weeding or layering. The design is printed directly onto the film, which can then be quickly transferred to the intended surface. This makes it an ideal choice for businesses that require quick turnaround times.

6. Customization: Direct-to-film printing allows for easy customization of designs. Whether it’s personalized clothing, promotional items, or one-of-a-kind artworks, this method enables designers to create unique and tailored pieces to meet the specific needs of their clients.

Conclusion

Direct-to-film printing has revolutionized the way designs are transferred onto various surfaces, offering numerous benefits to designers and businesses alike. With its high-quality prints, versatility, durability, cost-effectiveness, and time-efficiency, this technology has become a game-changer in the design industry.

Whether you are a fashion designer looking to create stunning apparel, an artist wanting to showcase your artwork on different mediums, or a business owner seeking personalized promotional items, direct-to-film printing is a versatile and efficient solution that can bring your ideas to life.

Embrace the power of direct-to-film printing and unlock a world of possibilities for your creative endeavors.